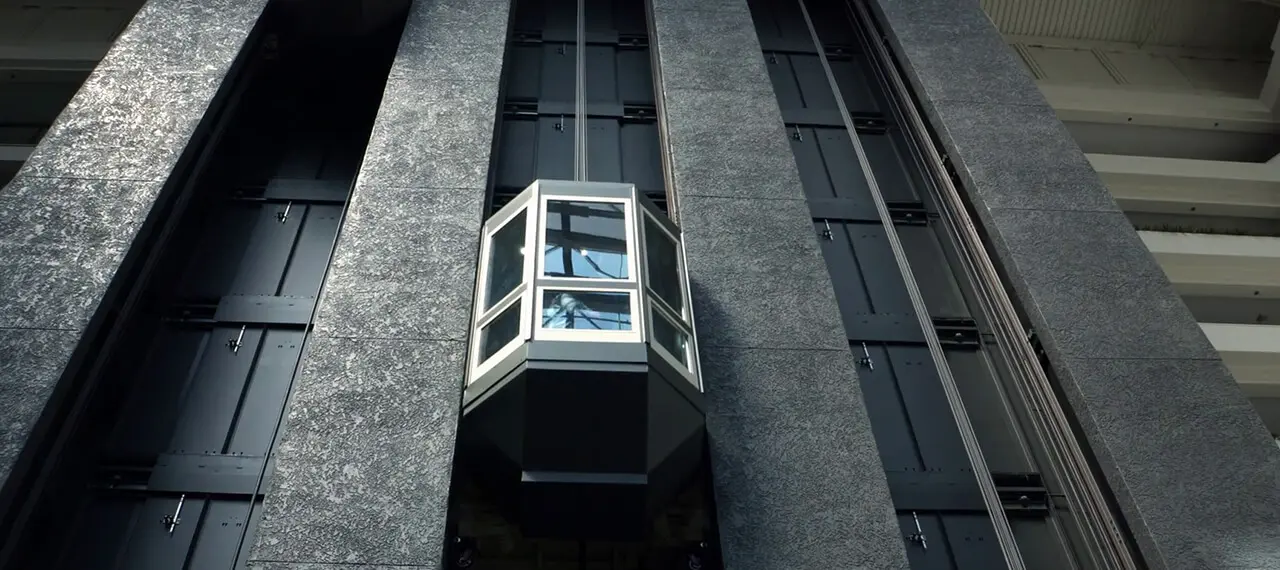

Elevators play a crucial role in modern buildings, ensuring smooth transportation of people and goods across floors. But have you ever wondered how engineers determine how many people or how much weight an elevator can handle? Calculating elevator capacity is not just about fitting people inside; it involves safety, efficiency, and compliance with regulations. Let’s break it all down step-by-step.

Why Is Calculating Elevator Capacity Important?

Calculating elevator capacity ensures buildings run efficiently and safely. From high-rise apartments to commercial towers, every building needs elevators designed for its specific needs. Underestimating capacity can lead to overcrowding, long wait times, and even accidents. On the other hand, overestimating can waste resources and space.

Key areas where elevator capacity calculations come into play include:

- Building design: Ensuring elevators can handle peak traffic times.

- Safety: Preventing overloading and ensuring passengers’ safety.

- Efficiency: Reducing wait times and improving the user experience.

Key Components of Elevator Capacity

Several factors affect elevator capacity. Let’s explore the three most important ones:

1. Weight Capacity

This is the maximum load an elevator can safely carry. It depends on:

- The strength of the motor and cables.

- Manufacturer specifications.

For instance, most passenger elevators have weight limits ranging from 1,000 to 5,000 pounds.

2. Space Capacity

This refers to the physical size of the elevator cabin. It determines how many people or how much cargo can fit comfortably.

- Standard passenger elevators provide 0.2–0.3 square meters per person.

- Freight elevators prioritize volume over passenger comfort.

3. Usage Patterns

Different buildings have different elevator demands.

- Residential buildings may see peak usage during mornings and evenings.

- Commercial buildings often experience high traffic during office hours.

Understanding these patterns is vital for optimizing elevator capacity.

Steps to Calculate Elevator Capacity

Here’s a simple, step-by-step process to calculate elevator capacity:

1. Determine Weight Capacity

- Check Manufacturer Specifications: Look at the elevator’s user manual or technical sheet for the maximum weight limit.

- Convert Weight to Passenger Count: Divide the weight limit by the average weight per person (typically 150–200 pounds).

Example: If an elevator’s weight limit is 2,000 pounds, it can carry 10–13 people.

2. Calculate Space Capacity

- Measure Floor Area: Measure the internal floor area of the elevator in square meters.

- Use Standard Space Requirements: Divide the floor area by 0.2–0.3 square meters per person.

Example: An elevator cabin with 2.5 square meters can hold 8–12 people comfortably.

3. Combine Weight and Space Limits

- Compare the weight and space calculations. The smaller number becomes your effective capacity. For example, if weight limits allow 10 people, but space fits 8, the capacity is 8.

4. Adjust for Real-World Factors

- Passenger diversity: Include heavier individuals or those carrying luggage.

- Uneven weight distribution: Ensure weight doesn’t tilt the elevator.

Safety and Regulatory Considerations

A. Local Building Codes

Every region has specific building codes for elevator design. Check local regulations to ensure compliance.

B. Regular Maintenance

- Load tests ensure elevators stay within their designed limits.

- Overload prevention mechanisms, like alarms or sensors, add an extra layer of safety.

C. Emergency Preparedness

Proper capacity planning prevents accidents during emergencies like evacuations.

Practical Examples

Example 1: Residential Elevator

A residential elevator has a cabin area of 3 square meters and a weight limit of 2,500 pounds.

- Space capacity: 3 ÷ 0.3 = 10 people.

- Weight capacity: 2,500 ÷ 200 = 12 people.

Final capacity = 10 people (lower of the two).

Example 2: Freight Elevator

A freight elevator has a weight limit of 5,000 pounds and a floor area of 4 square meters.

- Weight capacity dominates since cargo doesn’t follow standard space requirements.

Final capacity depends on the size and type of goods transported.

Advanced Considerations

A. Elevator Speed and Travel Distance

Faster elevators can handle more trips, reducing the need for high capacity. Long travel distances may demand larger cabins.

B. Traffic Analysis

Analyzing usage patterns helps optimize elevator size and number for large buildings.

C. Simulation Software

Modern tools can simulate traffic and calculate optimal elevator capacity for complex buildings.

Conclusion

Accurately calculating elevator capacity is crucial for safety, efficiency, and a smooth user experience. By understanding weight limits, space constraints, and usage patterns, building designers can create elevators tailored to their needs.

Final Tip: Always prioritize safety and consult experts or software tools for advanced projects. If you’re planning a building, start by analyzing the peak usage and space requirements to get it right. Supertech Elevator is here to help with expert insights and top-tier elevator solutions.